Business Areas

Best technology in clean hydrogen energy, high pressure gas, disaster prevention business, safety equipment

Retest Of High Pressure Gas Cylinder

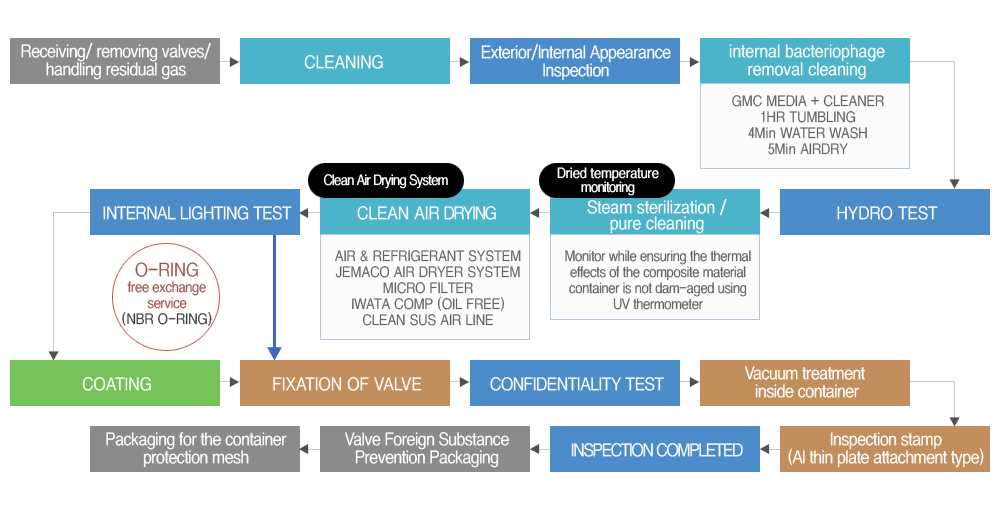

FLOW - CHART

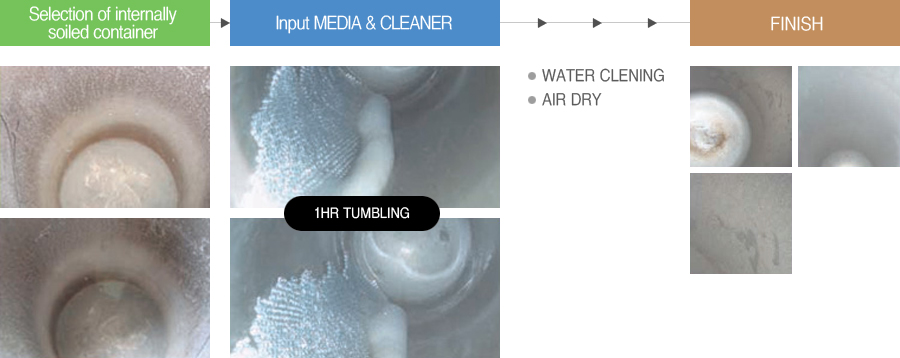

TANK CLEANING SYSTEM of GMC

TUMBLING MEDIA

TANK CLEANER

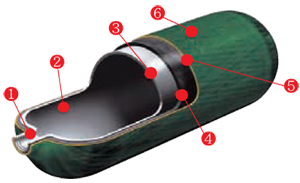

COMPOSITE CYLINDER

2. Inert internal finish

3. Aluminum liner

4. Carbon fiber

5. Glass-fiber

6. Epoxy gel-coat finish

Complete removal of impure gas inside the container

Removes impure gases and moisture that can be left behind in the container during the testing procedures by removing the impure gases inside the container through vacuum processing with vacuum pressure of more than -750mmHg

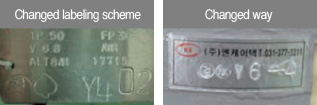

Marking with engraved seal stamping of test in new format

Protection mesh for prevention of impact on the container

Information On Product Testing

NKTECH Co., Ltd., an institution specializing in gas testing, executes not only retesting of the industrial pressurized container but also retesting of ultra-large container and air respirator container as well as retesting of valve for special gas container with built-in diaphragm. Having established ourselves as an institution specializing in testing of pressurized container and container valves, we shall ardently strive to remunerate the passionate support our clients have given us by assertively fulfilling the requirement of our clients.